Imagine a trusty workhorse, strong and reliable, ready to tackle any task. The Massey Ferguson 35 is just that, a legend among farm equipment, known for its durability and power. But even the sturdiest machines need a steady flow of fuel to keep them running. That’s where the fuel system comes in, a complex but vital network that ensures each drop of diesel reaches the engine’s heart. Unraveling the mysteries of the Massey Ferguson 35 fuel system is a journey into the mechanics of this iconic tractor, a journey that will equip you with the knowledge to handle any fuel-related challenge.

Image: www.carburetor-parts.com

Understanding the Massey Ferguson 35 fuel system is crucial for any owner or enthusiast. It’s not just about maintaining your tractor; it’s about ensuring the longevity and peak performance of your trusty workhorse. Whether you’re troubleshooting a stubborn starting issue or simply want to delve deeper into the inner workings of this legendary machine, this guide will provide you with a comprehensive overview of the Massey Ferguson 35 fuel system, from the humble fuel tank to the intricate injectors that deliver the power. Get ready to unlock the secrets of this essential system and master the art of keeping your MF 35 in top shape.

The Fuel System: A Lifeline of Power

The fuel system of the Massey Ferguson 35 acts like a circulatory system for the engine, delivering the vital fuel it needs to operate. This intricate network involves several key components, each playing a crucial role in ensuring smooth and efficient operation. Let’s break down each component and explore its function in the grand scheme of the fuel delivery process.

Fuel Tank: The Reservoir

The fuel tank is the starting point of the journey, the reservoir where the diesel fuel is stored. The tank is typically located on the rear of the tractor, offering a convenient access point for refueling. The fuel tank itself is usually made of sturdy steel, capable of handling the demands of rugged farming environments. The most important aspect of the fuel tank is its cap, which provides a tight seal to prevent leaks and spills, ensuring safe and efficient fuel storage.

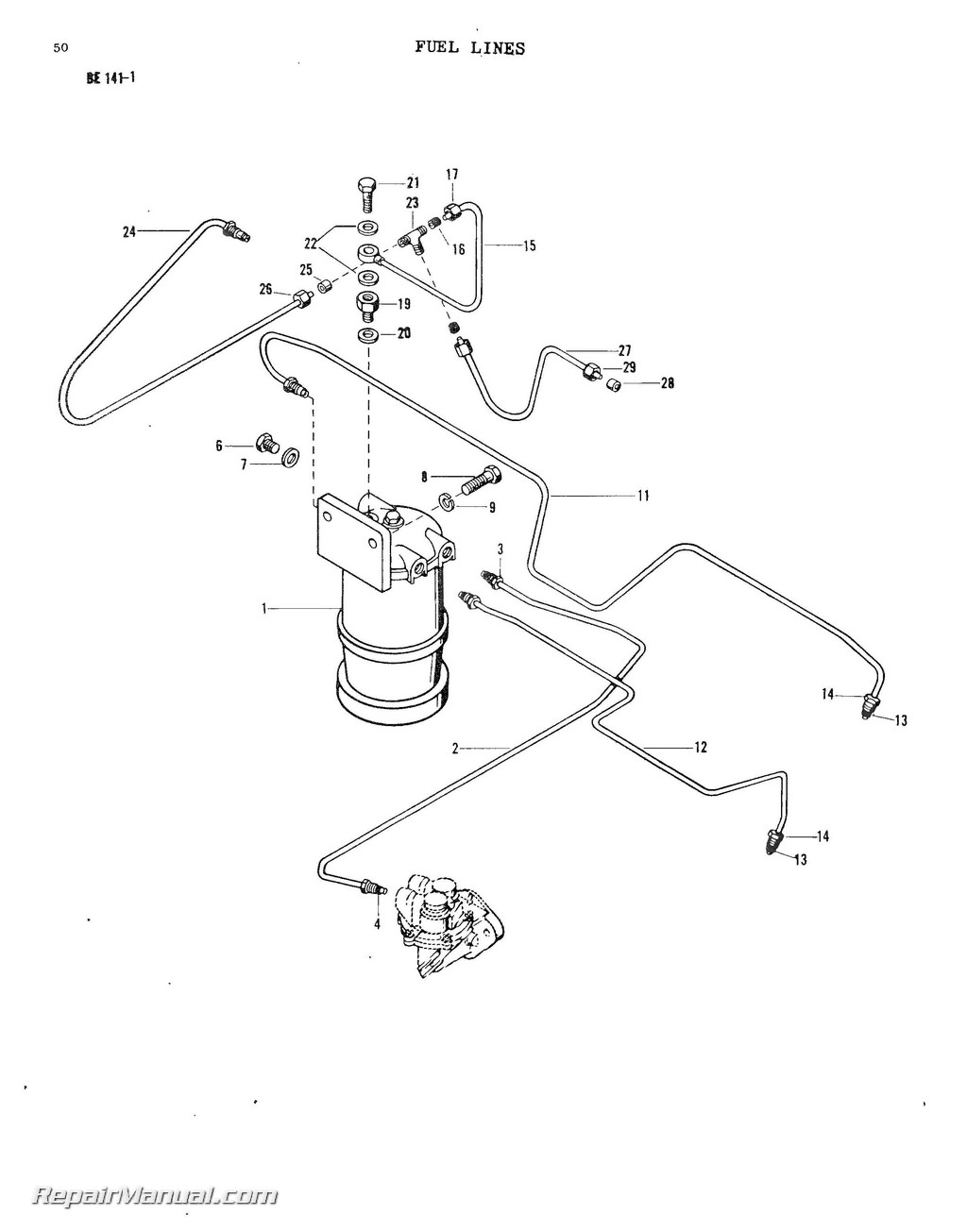

Fuel Lines: Delivering the Power

From the fuel tank, the fuel embarks on its journey through a network of fuel lines. These lines are typically made of durable rubber or steel, designed to withstand the pressure and abrasion of the tractor’s operation. Fuel lines are responsible for channeling the fuel from the tank to the fuel pump, ensuring a steady flow of diesel to the engine. Keep an eye out for any signs of wear or damage in the lines, as leaks can significantly impact the tractor’s performance.

Image: hanenhuusholli.blogspot.com

Fuel Filter: The Guardian of Cleanliness

Before reaching the engine, the fuel must pass through a critical checkpoint: the fuel filter. This vital component acts as a guardian against impurities, preventing dirt, debris, and water from contaminating the delicate engine parts. The fuel filter is typically located near the engine, where it traps any foreign particles, ensuring clean fuel reaches the injectors. Regular replacement of the fuel filter is crucial for optimal engine performance and longevity. A clogged filter can restrict fuel flow, leading to reduced power and even engine damage.

Fuel Pump: The Driving Force

The fuel pump acts as the driving force of the fuel system, pushing the fuel through the lines and towards the engine. In the Massey Ferguson 35, a mechanical pump is typically employed, powered by a shaft connected to the engine. Through a series of gears and levers, the fuel pump creates the necessary pressure to propel the fuel along its path. Proper pump operation is critical; a faulty pump can lead to insufficient fuel pressure, resulting in poor engine performance or even failure to start.

Fuel Injectors: Delivering the Fuel

Finally, the fuel arrives at its destination: the fuel injectors. These precision devices are responsible for delivering the fuel directly to the engine’s combustion chambers. Injectors take the fuel under pressure and atomize it into a fine mist, ensuring optimal combustion. The timing and precision of the fuel injection process are critical for engine performance. Wear and tear on injectors can lead to problems such as rough idling, power loss, and increased emissions.

Maintaining a Healthy Fuel System: Essential Steps

To ensure your Massey Ferguson 35 runs smoothly and efficiently, keeping the fuel system in top shape is crucial. Here are some essential tasks you can perform to ensure longevity and prevent unnecessary repairs:

- Regular Fuel Filter Replacement: Regularly changing the fuel filter is essential. A clogged filter can hinder fuel flow, impacting engine performance. Consult your tractor’s manual for recommended replacement intervals.

- Fuel Tank Maintenance: Keep the fuel tank clean and free from debris. Regularly inspect the tank for leaks or damage, and ensure the fuel cap is tightly sealed for optimal fuel storage.

- Fuel Line Inspection: Visually inspect fuel lines for signs of wear, cracks, or leaks. Replace any damaged lines promptly to prevent fuel leaks and ensure a steady fuel flow.

- Fuel Pump Maintenance: Check the fuel pump for proper operation. Listen for any unusual noises or signs of leakage. If you suspect a malfunctioning pump, seek professional repair.

- Injector Cleaning: Fuel injectors can become clogged over time. Regularly cleaning or replacing injectors can improve fuel efficiency and prevent engine problems. Consult a qualified mechanic for professional injector cleaning or replacement.

Troubleshooting Fuel System Issues: Common Problems and Solutions

Sometimes, despite your best efforts, fuel system problems can arise. Here’s a guide to some common issues and potential solutions:

Engine Won’t Start:

- Empty Fuel Tank: Check the fuel level to ensure there is enough fuel to start the engine.

- Clogged Fuel Filter: Replace the fuel filter if it is dirty or clogged. A clogged filter can restrict fuel flow, preventing the engine from starting.

- Fuel Pump Malfunction: If the fuel pump is not working properly, it won’t deliver fuel to the engine. Check the pump for signs of damage or leakage. Seek professional repair if necessary.

- Fuel Line Blockage: Inspect the fuel lines for blockages or kinks. Clear any obstructions or replace damaged lines.

Engine Running Rough or Losing Power:

- Clogged Fuel Filter: A clogged filter can restrict fuel flow, leading to rough running or loss of power. Replace the filter as needed.

- Fuel Injector Issues: Clogged or worn injectors can cause rough running or power loss. Clean or replace injectors as needed.

- Air in Fuel Line: Air bubbles in the fuel line can interrupt fuel flow, leading to engine problems. Bleed the fuel lines to remove any air bubbles.

Fuel Leaks:

- Loose Fuel Connections: Check all fuel line connections for tightness. Tighten any loose connections.

- Damaged Fuel Lines: Visually inspect fuel lines for cracks, tears, or wear. Replace any damaged lines.

- Leaking Fuel Tank: Inspect the fuel tank for signs of damage or leakage. Repair or replace the tank as needed.

- Leaking Fuel Pump: Check the fuel pump for signs of leakage. Seek professional repair if needed.

Massey Ferguson 35 Fuel System Diagram

https://youtube.com/watch?v=GUQDl35_9dY

The Fuel System: A Lifeline to Your Workhorse

The Massey Ferguson 35’s fuel system is a marvel of engineering, a testament to the tractor’s reliability and durability. Understanding the fuel system is key to ensuring your tractor operates at peak performance. From regular maintenance to troubleshooting common issues, a firm grasp of this system will empower you to maintain your trusty workhorse. So, delve into the details, become familiar with each component, and you’ll be well on your way to mastering the art of keeping your MF 35 running strong for years to come.