Have you ever stared at a confusing array of engine parts, wondering which one fits your riding mower? The world of small engines can be a maze of specifications, but with the right information, even the most daunting task becomes manageable. This is where understanding Briggs & Stratton shaft sizes comes in. Whether you’re replacing a worn-out engine, customizing your equipment, or simply curious about the inner workings of your lawnmower, navigating this chart is essential.

Image: www.briggsandstratton.com

The shaft size is a critical component that dictates the compatibility of your engine with other equipment. It determines how your engine connects to the machinery it powers. This guide dives deep into the world of Briggs & Stratton shaft sizes, demystifying the numbers and clarifying how this information makes your DIY projects a breeze.

Understanding Shaft Size

Before we dive into the details of the Briggs & Stratton shaft size chart, let’s clarify what it means. “Shaft size” refers to the diameter of the output shaft on the engine. This is the metal rod extending from the engine’s casing, onto which the blades, pump, or other machinery will be connected.

Why is Shaft Size Important?

The shaft size defines the type of equipment that can be used with a specific engine. If you have a riding mower with a 1-inch shaft and install an engine with a 5/8-inch shaft, you won’t be able to attach the blades. To ensure compatibility, you must choose an engine with a shaft size that is compatible with your mower, tiller, pump, or other equipment.

Exploring the Briggs & Stratton Shaft Size Chart

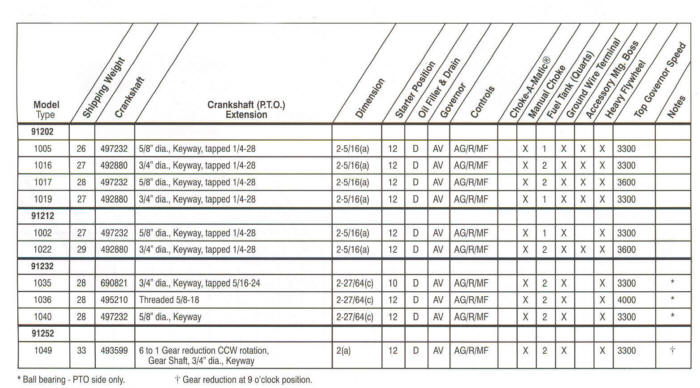

Briggs & Stratton, a leading manufacturer of small engines, provides a comprehensive chart detailing the shaft sizes for their diverse lineup of engines. While this chart may seem daunting at first, it’s a valuable tool for ensuring compatibility.

Image: www.smallenginesuppliers.com

1. Interpreting the Chart: Key Elements

The chart is usually organized with columns representing engine series, models, and corresponding shaft sizes.

- Engine Series: This identifies the engine family, such as the “Series 19” or “Series 692.”

- Model: This specifics an individual engine within a series, with examples like the “190432” or “692103.”

- Shaft Size: This column outlines the diameter of the output shaft, usually expressed in fractions of an inch. Typical Briggs & Stratton shaft sizes include 5/8-inch, 3/4-inch, and 1-inch.

2. Finding Your Match

To find the right shaft size for your equipment, you need to

identify the make and model of your existing engine or the one you plan to purchase. Locate the engine series and model within the Briggs & Stratton shaft size chart. This will reveal the corresponding shaft size, ensuring compatibility with your current or future equipment.

3. Beyond the Chart: Additional Considerations

While the Briggs & Stratton shaft size chart serves as a fundamental guide, it’s essential to consider other aspects of engine compatibility.

- Shaft Type: Different engine models may have varying shaft types, such as “D-shaped” or “round.” Ensure your engine and equipment have the same shaft type for a secure connection.

- Keyway: The keyway is a slot on the shaft that ensures proper alignment with the equipment. Ensure your engine and equipment have compatible keyways.

Troubleshooting Shaft Size Issues

Even when using the Briggs & Stratton shaft size chart, you may encounter challenges. Don’t be discouraged! There are solutions to common problems.

1. Adapter Plates: Bridging the Gap

If your engine and equipment have incompatible shaft sizes, an adapter plate can be a lifesaver. These plates allow you to connect different-sized shafts. Just be sure to choose a plate that is designed for the specific engine and equipment combination.

2. Custom Solutions: When Adapters Fall Short

For complex fitting scenarios, custom solutions might be necessary. This might involve machining parts or consulting a qualified mechanic skilled in fabrication work. Before venturing into customization, weigh the complexity and cost against the benefits.

Staying Informed & Mastering Your Equipment

The Briggs & Stratton shaft size chart is a potent tool, but it’s not a substitute for understanding the essential elements of small engine operation. Here’s a bit of practical knowledge to elevate your DIY prowess:

1. The Importance of Proper Maintenance

Regular maintenance is crucial for maximizing your engine’s life and performance. This includes oil changes, air filter cleaning, spark plug replacement, and carburetor adjustments. You can find detailed guides on the Briggs & Stratton website.

2. Addressing Common Engine Problems

Even with proper maintenance, engine issues can arise. Recognizing the signs of a faulty engine is essential. Common problems include:

- Difficulty starting

- Lack of power

- Engine overheating

- Unusual noises

3. Seeking Expert Help: When DIY Isn’t Enough

While tackling small engine projects can be rewarding, sometimes professional assistance is necessary. Don’t hesitate to consult a qualified mechanic for complex repairs or installations. They possess the experience and tools to ensure the best possible outcome for your equipment.

Briggs And Stratton Shaft Size Chart

Conclusion

Knowing the Briggs & Stratton shaft size chart is a fundamental step toward understanding your small engine equipment. By decoding this chart and understanding the intricacies of shaft sizes and compatibility, you’ll be better equipped to maintain, repair, and even customize your equipment. Remember, with the right information, tackling small engine projects can be an empowering and enjoyable experience. So, explore the chart, embrace the knowledge, and confidently take on your next DIY adventure!