The whirring hum of a smoothly operating robotic arm in a manufacturing facility is a symphony of precision and efficiency. But what happens when that melody falters, replaced by an ominous code flashing on your Allen-Bradley Kinetix 6000 drive? This is where understanding the language of fault codes becomes essential. As a seasoned automation engineer, I’ve encountered my fair share of these cryptic messages, and let me tell you, they can be nerve-wracking. But fear not, deciphering these codes is not as daunting as it might seem. Today, we’ll delve into the world of Kinetix 6000 fault codes, equipping you with the knowledge to troubleshoot drive system issues and get your systems back up and running in no time.

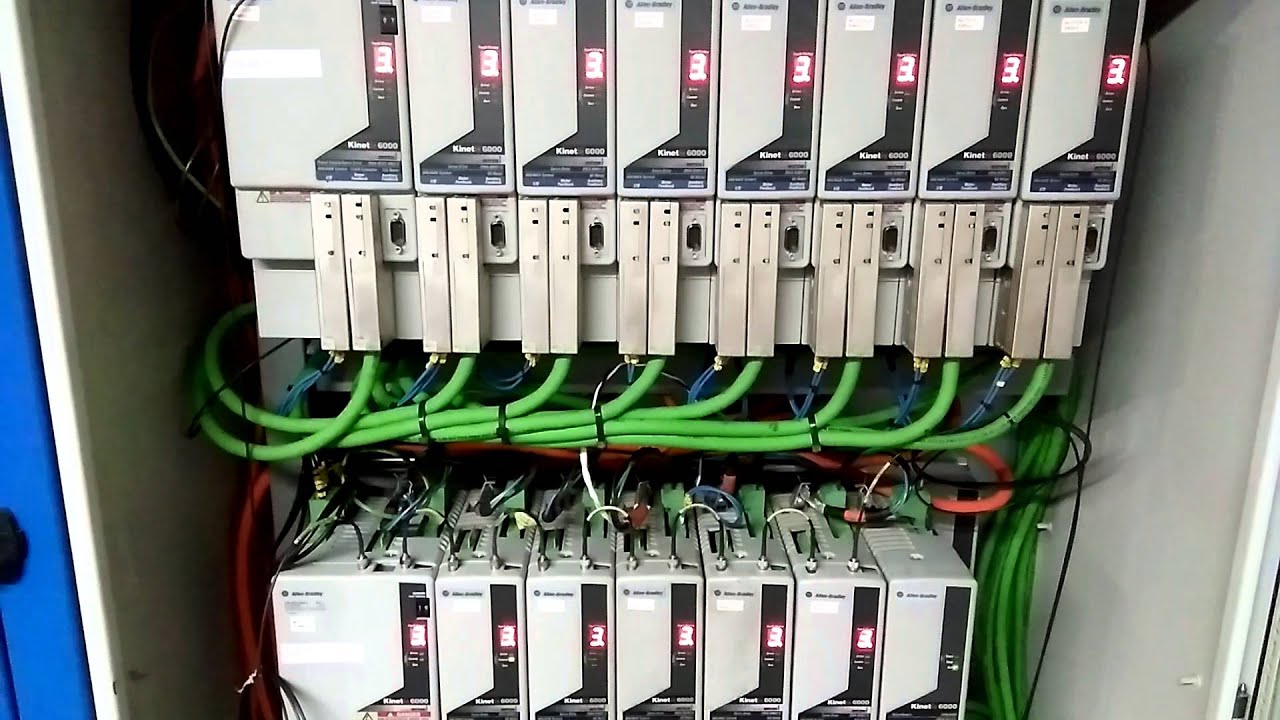

Image: www.rockwellautomation.com

Imagine you’re running a critical production line, and suddenly, the robot arm freezes mid-motion. The screen displays a mysterious code that sends a chill down your spine. This isn’t just a minor glitch; it’s a potential bottleneck, halting production and impacting your bottom line. That’s where comprehensive understanding of these fault codes comes in. Each code carries a specific meaning, providing valuable insights into the root cause of the problem.

Navigating the World of Kinetix 6000 Fault Codes

The Allen-Bradley Kinetix 6000 drive system, a cornerstone of industrial automation, is designed for reliability and performance. However, like any sophisticated technology, it can encounter occasional glitches. Understanding the Kinetix 6000 fault codes is crucial for diagnosing and resolving these issues quickly and effectively. These codes act as a communication bridge between the drive and the technician, providing valuable insights into the underlying issue.

Fault codes are displayed on the Kinetix 6000 drive’s LCD screen or can be accessed through the drive’s built-in software interface. Each code is a unique combination of letters and numbers that represents a specific event or condition. The codes range from straightforward issues like communication errors to more complex errors indicating problems with the motor, power supply, or even the drive’s internal components. These intricate messages are your guide to pinpointing the cause of the problem.

Deciphering the Language: Understanding the Structure of Kinetix 6000 Fault Codes

Decoding Kinetix 6000 fault codes requires a structured approach. Each code is made up of distinct elements that carry specific information. Typically, a code will start with a two-letter prefix, followed by a four-digit number. The prefix is often indicative of the drive system component experiencing the error. For instance, “OC” might represent an overload condition, while “FB” could signify a feedback issue. The numerical part of the code further details the specific nature of the error.

Let’s examine an example. A common Kinetix 6000 fault code is “OC0005”. This code, broken down, reveals that the “OC” prefix signifies an overload condition. The “0005” component suggests a specific type of overload, potentially indicating that the motor’s current has exceeded the allowable threshold. Understanding this structure allows you to quickly pinpoint the potential problem area.

Utilizing Resources: Your Guide to Effective Troubleshooting

The good news is, you don’t have to decipher these codes alone. Allen-Bradley provides a wealth of resources to aid your troubleshooting efforts. Their official documentation, accessible on their website, offers detailed descriptions of each Kinetix 6000 fault code. These descriptions usually include the potential causes, recommended troubleshooting steps, and potential solutions. This documentation serves as your primary reference point for understanding and resolving drive system errors.

Beyond official documentation, online forums and communities dedicated to Allen-Bradley products can be invaluable sources of information. Sharing your experience with other users allows you to tap into a collective knowledge base, often finding solutions and insights that you might miss on your own. By leveraging these resources, you can elevate your troubleshooting skills and efficiently address Kinetix 6000 errors.

Image: www.youtube.com

Troubleshooting Tips and Expert Advice

Here are some key tips to make your troubleshooting process more effective:

- Start with the basics: Double-check your connections, power supply, and ensure the drive is properly grounded.

- Verify configuration: Ensure that the drive is appropriately configured for the motor and application. Minor configuration errors can lead to errors.

- Utilize diagnostic tools: Take advantage of the drive system’s built-in diagnostics. These tools can help you pinpoint the problem area by providing additional information.

- Document your findings: Keep detailed notes of your observations, fault codes, and troubleshooting steps. This documentation is crucial for tracking progress and ensuring consistency when working with the system.

- Contact support: If you’re unable to resolve the issue, don’t hesitate to contact Allen-Bradley technical support. Their expertise can be invaluable in resolving complex problems.

Remember, troubleshooting is a process of elimination. Starting with the most common causes and systematically narrowing down the possibilities is essential. It’s also important to approach troubleshooting with a calm and methodical mindset, carefully analyzing the information available before making any changes to the system.

Frequently Asked Questions About Kinetix 6000 Fault Codes

Q: What does a fault code ending in “0000” mean?

A fault code ending in “0000” usually signifies a generic error. This type of code often needs further investigation to determine the specific cause.

Q: How often should I expect to encounter fault codes in a Kinetix 6000 drive system?

While the Kinetix 6000 drive systems are designed for reliability, fault codes can occur, particularly in demanding applications or when there are environmental factors affecting the system. Proper maintenance and preventive measures can help minimize the frequency of these events.

Q: What are some common causes of Kinetix 6000 fault codes?

Some common causes include motor issues like winding faults, overheating, or improper connections, power supply problems, communication errors, and configuration errors.

Allen Bradley Kinetix 6000 Fault Codes

Conclusion

Mastering the language of Kinetix 6000 fault codes is essential for any automation engineer or technician. Understanding the structure, utilizing resources, applying troubleshooting tips, and remembering to document your findings empowers you to navigate these codes effectively and address drive system issues with confidence. Remember, every fault code holds a unique story that can be deciphered with the right approach.

Are you ready to delve deeper into the world of Allen-Bradley Kinetix 6000 fault codes? If you have any questions or would like to share your own troubleshooting experiences, please leave a comment below. Let’s build a community of knowledge and support around these essential codes!